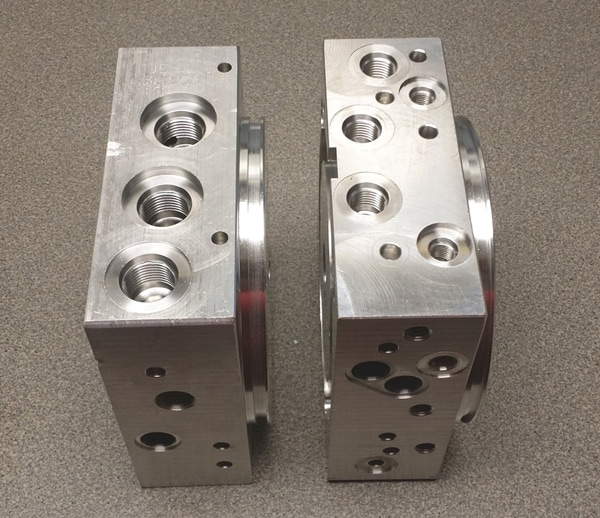

At Burr Off, we are an ISO 9001:2008 certified provider of thermal deburring services, and we were contracted to provide a thermal deburring of a 6061-T6511 aluminum snow plow manifold. We removed all trace particulates from this manifold, which measured 2.850” in length, 2.750” in width, and 2.410” in height, while providing a final product that maintained the tightest tolerances of ±0.005”. After deburring, this manifold was thoroughly washed, rinsed, and dried to remove any remaining chips. We then employed our 8-50X microscope with an integrated scale to measure and inspect for burrs on all surfaces of the manifold. Meticulous visual inspections were performed at set-up, during the process, and for the final inspection. The final results pleased our customer greatly. We now deburr 15,000 of these aluminum manifolds annually for our Milwaukee, Wisconsin customer, which are completed and delivered with average turnaround times of just 2 to 4 days.

To learn more about this project or any of our other finishing services, please contact us directly.

PROJECT HIGHLIGHTS FOR THERMAL DEBURRING OF ALUMINUM MANIFOLDS

| Product Description | Thermal Deburr of Aluminum Manifold |

| Capabilities Applied/Processes | Primary:

Secondary:

|

| Overall Part Dimensions | Length: 2.850" Width: 2.750" Height: 2.410" |

| Tightest Tolerances | ±0.005" |

| Pre-Processes | Wash and Rinse |

| Post Processes |

|

| Material Used | 6061-T6511 Aluminum |

| Material Finish | Wash, Rinse, Dry |

| In process testing/inspection performed | Equipment used:

Multiple Inspection points:

|

| Volume | 15,000 annual usage |

| Delivery/Turnaround Time | 2-4 days |

| Delivery Location | Milwaukee, WI |

| Standards Met | Customer Specification ISO 9001:2008 |