At Burr-Off, we have extensive experience in providing thermal deburring services to a wide range of customers including the automotive, hydraulic, and die casting industries. Thermal deburring is a unique process wherein burrs are oxidized by a tightly controlled combination of heat and pressure. The short duration of the heat application incinerates the burr without distortion to the part itself. Thermal deburring is most applicable to parts with flag type burrs that are created by sharp machining tools. This type of burr has a uniform thickness and consistent shape. To prevent distortion to the part itself, the minimum required wall thickness for thermal deburring is approximately 0.030″. As wall thicknesses or part features approach the same thickness as the burr, the risk of warping and distortion increases. We can evaluate individual parts to assess whether thermal deburring can successfully be used on the component.

We are capable of deburring a variety of metals including iron, steel, and die cast metals. Prior to deburring, loose chips and machine oil is removed from the part. Contaminants interfere with the accuracy and consistency of the deburring process. Excess chips can cause undesired splatter on the part surface. Because the parts are exposed to elevated temperatures during the deburring process, some descaling and cleaning are required. Our proprietary cleaning bath removes scale and oxidation, leaving a clean part surface. A rush inhibitor is applied after cleaning to protect the metal during shipping and storage. Components are inspected and packaged according to customer specifications. Because thermal deburring is such an efficient process, most projects can be turned around within 2 to 3 days. For more information about our thermal deburring capabilities, see the table below, or contact us directly.

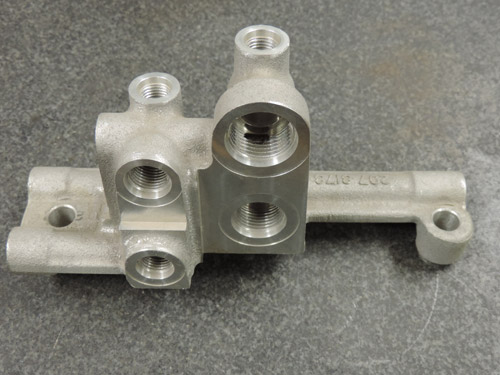

PAST PROJECT GALLERY

- Thermal Deburring of Adapter for the Fluid Power Industry

- Thermal Deburring of Plate for the Fluid Power Industry

- Thermal Deburring of a Mirror Mount for the Automotive Industry

- Thermal Deburring and Dry Abrasive Blasting of Zinc Die Casting for the Automotive Industry

- Vibratory Deburring of Spring Guides for the Hydraulic Industry

- Thermal Deburring of Aluminum Manifolds for a Snow Plow

THERMAL DEBURRING CAPABILITIES

| Capability | Thermal Deburring |

| Applicable Burr Type | Flag Burrs |

| Materials | Aluminum Dura-Bar Zinc Die Cast Aluminum Die Cast Steel Iron Brass Copper |

| Diameter | Up to 11.875" |

| Height | Up to 14.5" |

| Minimum Part Wall Thickness | 0.030" |

| Pre Treatment Process | Degreasing Loose Chip Removal |

| Post Treatment Process | Scale Removal Application of Rust Inhibitor As Applicable |

| Inspection | 10X Microscope Borescope |

| Additional Services | Vibratory Deburring & Finishing Dry Abrasive Blasting Packaging Kanban Management |

| Production Volume | Low Volume High Volume |

| Lead Time | 2-3 Days Typical |

ADDITIONAL INFORMATION

| Industry Focus | Automotive Hydraulic Die Casting Aerospace Machine Tool Appliance Dentistry Agricultural Equipment |

| Industry Standards | ISO 9001:2008 Certified DNV |